Foshan Zeao Metal Material CO.,LTD was founded in 2016,they are primarily approved to get production license in China industry.

Foshan Zeao Metal Material CO.,LTD are guided by market, base on science and technology, and always insist in rule of quality determines benefit. With the efficient management system, excellent technology professional, advanced equipment, excellent manufacture technical and stringent quality standards, Zeao’s products are well sold both in domestic and overseas market. The product lines are mainly involved in constructional and industrial profiles. Besides the casement windows, sliding window and glass curtain wall profiles, we have developed specific industrial profiles according to marketing needs such as energy-saving thermal-break profiles, aluminum profiles for decoration.

Zeao always adheres to an enterprise spirit of “diligence and practicality”.

By rely on our own core technology and R&D ability and our full process from raw-material production to product development, we try our best to offer excellent services to users in such aspects as products, technology and quality.

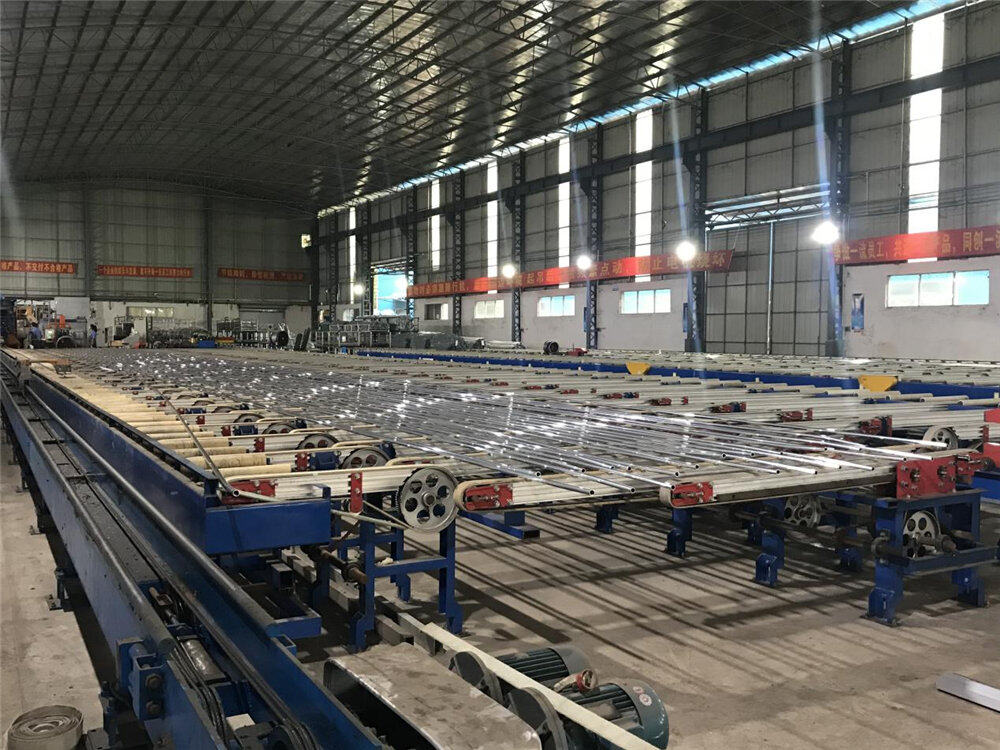

The Aluminum sheet/strip and foil production line manufactures highly precise pure aluminum and alloy sheet/strip and foil include 1000 series, 3000 series, 8011 and 5052, which thickness area is 0.06-500mm and 2000mm maximum width.

The annual output of aluminum profiles and aluminum sheet is nearly 100,000 tons, in which export volume makes up 50%.

Extruding equipments: 51. Extruding machines of various specifications,3000-9000 ton extruding lines:4. 600-2350ton extruding line:47.

CHARACTERISTICS

Heating the billet by gas-burning evenly and quickly,cooling the profile by balanced intensivecooling system,it can produce aluminum alloy of 2000 series、5000 series、7000 series andso on.Equipped with triplicate pulling system,it can produce different kinds of big size of industrial profiles with CCD 720mm used for traffic,electronic,building etc.

Anodizing and Electrophoresis Equipments: Vertical Anodizing and Electrophoresis production line:5. Horizontal Anodizing and Electrophoresis production line:2.

Powder Coating Equipments: Horizontal Coating Production line:3;Vertical Power Coating Production line:7.

PVDF Painting Equipments: Horizontal PVDF Production line:5; Vertical PVDF Production line:1.

Thermal Break Production line are 13 in total. Wood Grain Production lines are 6 in total.

THE CORE INDUSTRY

Through continuously increasing investment, we now have the leading domestic level of high efficiency, energy saving and environmental protection melting casting production line, intelligent extrusion equipment, automatic vertical oxidation production line, international mold processing center, deep processing center. Relying on the aluminum profiles provided by the same group, it cuts through every link of the aluminum mold industry and the aluminum mold production cycle, covering professional services such as design, raw material production, template production and processing.

MOLDS WAREHOUSE

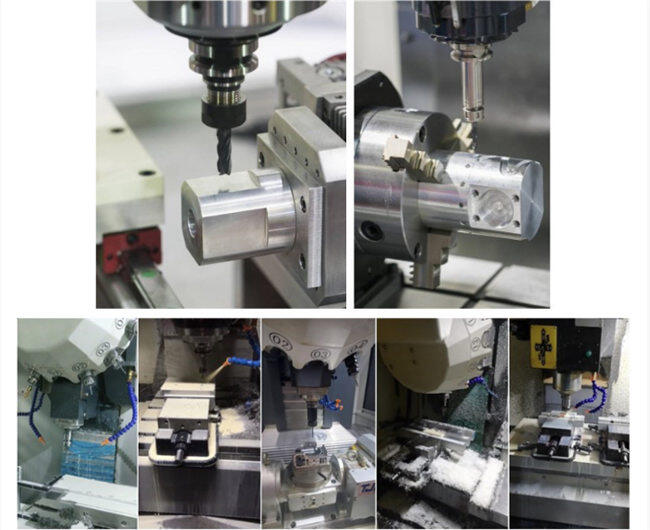

Mold machining center with manufacturing production line from the mold design, mold manufacturing, mold maintenance and a series of complete mold, has imported from Taiwan CNC machining center, wire cutting machining, CNC EDM and other advanced processing equipment, with an annual output of more than 3 sets of molds. The tool steels adopted by the center are all high quality special mould steels both at home and abroad, and computer management has been realized from the design, development and production of moulds. Leading design , advanced technology, exquisite customers, to produce first-class quality mold products.

CNC MACHINING PARTS

With precision casting and machining as the core business, the annual production capacity of more than 3,000 tons.Our products are mainly used in automobile, fluid chemical industry, food machinery, building hardware, medical equipment, industrial locks, electric power equipment, petroleum equipment, heat treatment equipment and other fields.The company has 220 sets of various precision casting equipment, 60 sets of machining equipment, and has a variety of testing equipment such as hardness tester, tensile testing machine, ultrasonic detector, spectrum analyzer, coordinate measuring instrument and so on.At present, more than 95% of the products are exported to the European Union, the United States, Japan, Australia and Taiwan and other countries and regions.

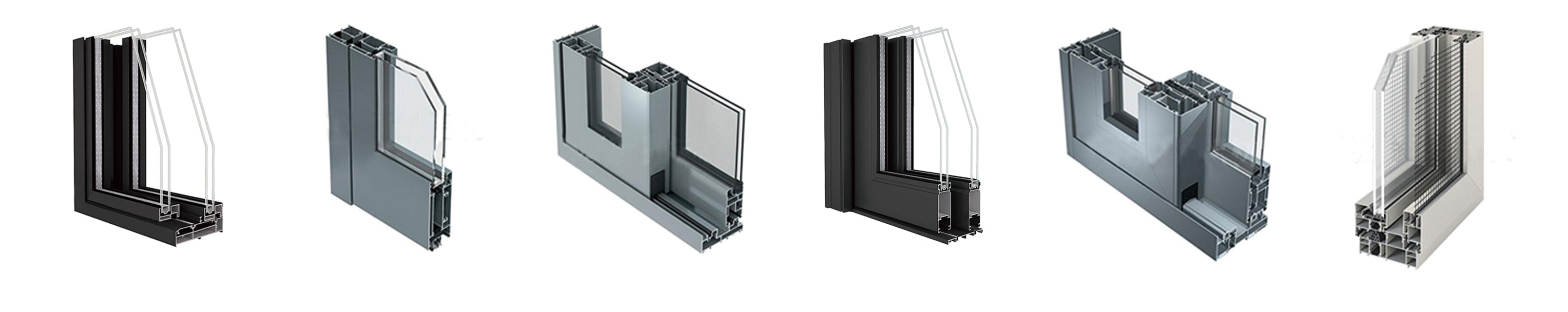

ALUMINIUM DOOR AND WINDOW PROFILE

The factory is divided into sliding door profiles, flat door profiles, flat Windows, push-pull Windows and other Windows and doors profiles, and the accessories storage area and into the shipping area, the capacity of aluminum warehouse material up to more than 2000 tons, effectively for customers to solve the problem of inventory. Window profile selection aluminum 6063 or 6061, with good stiffness, strength, corrosion resistance.Stress position thickening processing technology, doors and Windows more solid and durable.A variety of surface color can be selected to meet different styles of home furnishing, easy to integrate into the spot home decoration collocation, to meet different needs.

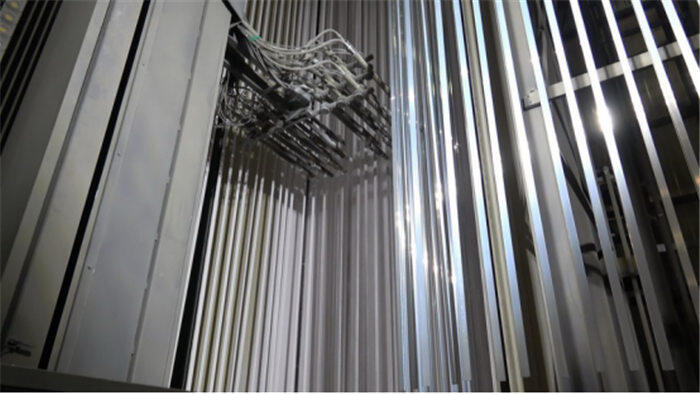

OXIDATION LINE

Oxidizing telecommunication equipment (7 pieces in total) : 5 vertical anodizing production lines, 2 horizontal anodizing electrophoresis production lines.It can produce high quality anodized electrolytic coloring products according to GB5237.2 and GB5237.3, European Qualanod, British BS3987 and Japanese JIS H8601 and JIS H8602 standards and specifications.In the electrophoresis, with electrophoresis, coloring and other advanced technology, the production of electrophoretic coloring aluminum profile does not produce any pollution, can meet the requirements of a variety of advanced decoration, under normal conditions of use, with at least 15 years of weatherability.

POWDER COATING LING

The company has imported more than one world’s top spraying equipment from Switzerland,and has built 2 spraying production lines,with an annual capacity of 60 thousand tons.Powder coating,the use of world famus Akesu(AKZO) a variety of weather resistant powder for the production of raw materials,its cottlorful colors for various styles of building provides a broad choice of space.Under normal service conditions,the company produces sprayed aluminum products with at least 15 years wetaher resistance,especially suitable for use in a variety of harsh environments.

ALUMINUM PLATE & COIL

Deep ploughing aluminum processing for more than 10 years, three aluminum products cover 1 series, 2 series, 3 series, 4 series, 5 series, 6 series, 7 series, 8 series aluminum alloy series, the main products are 1060 aluminum plate, 3003 aluminum plate, 3104 aluminum plate, 5052 aluminum plate, 5083 aluminum plate, 5182 aluminum plate, 6061 aluminum plate, 7075 aluminum plate, 2A12 aluminum plate and so on.Products are widely used in automotive, mold, ship, packaging container, architectural decoration, electronic communications, petrochemical, printing and platemaking and other fields.

FINAL PRODUCTS

WAREHOUSEAutomatic packaging production line, intelligent finished goods warehouse, automated warehouse, intelligent shuttle and other packaging logistics equipment, to achieve a one-stop packaging logistics intelligent. In line with the standardization of enterprise production behavior standards.