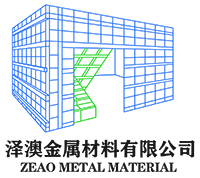

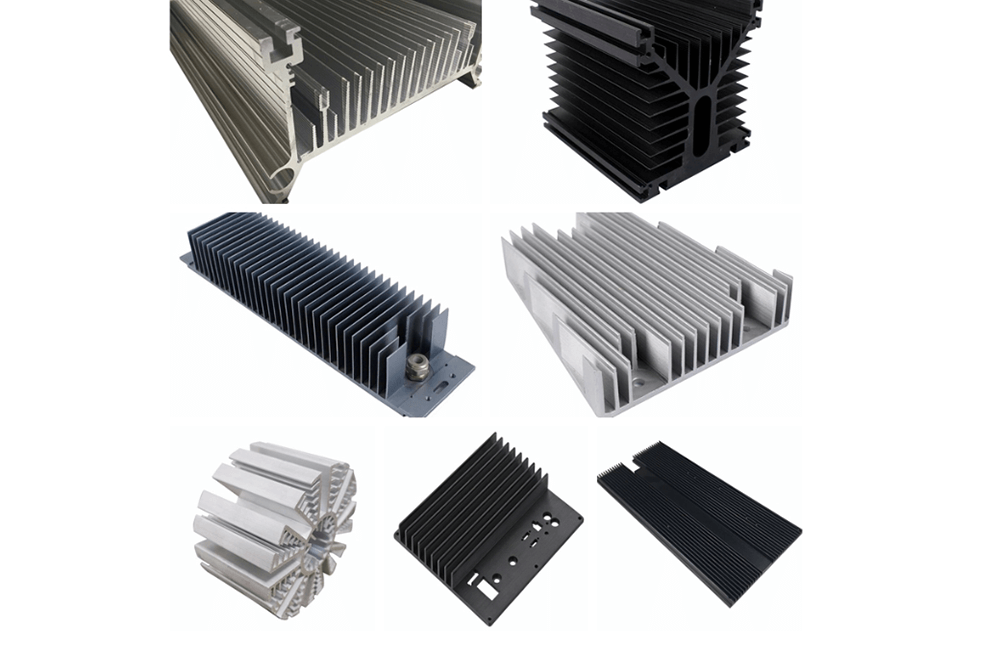

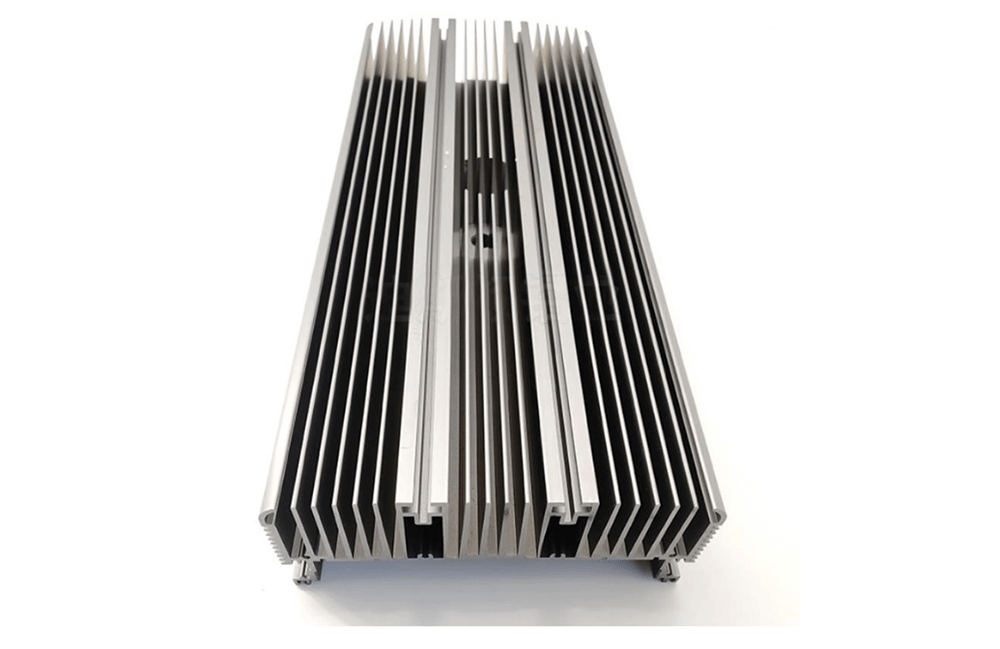

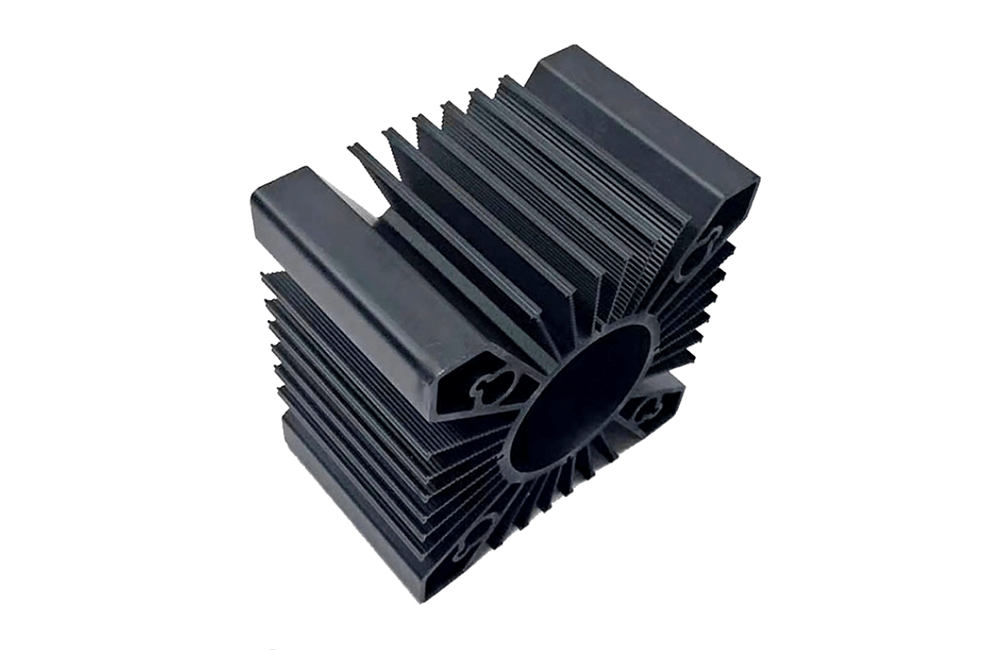

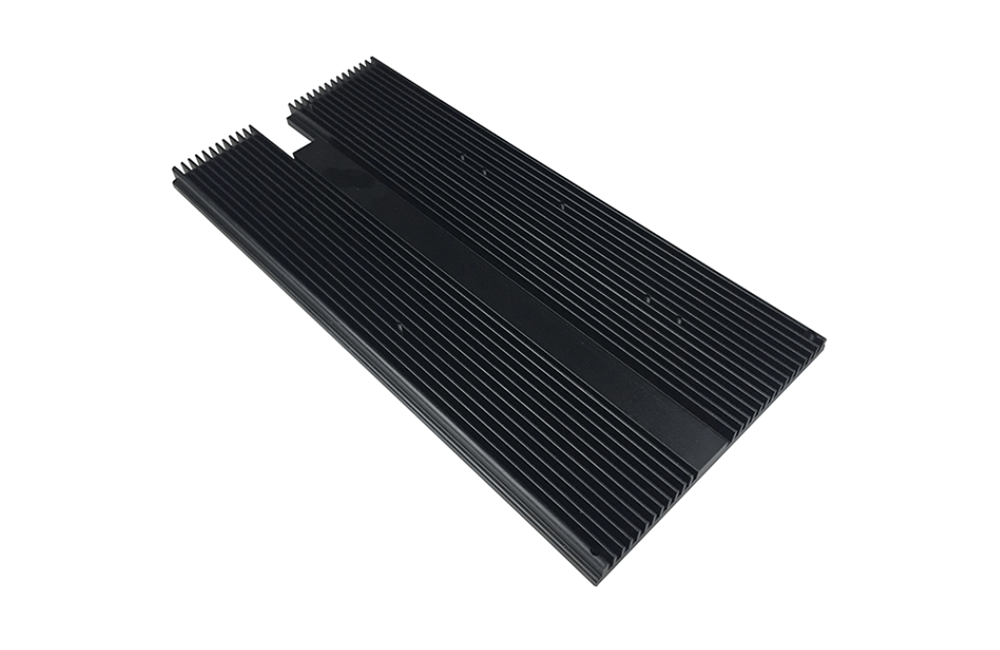

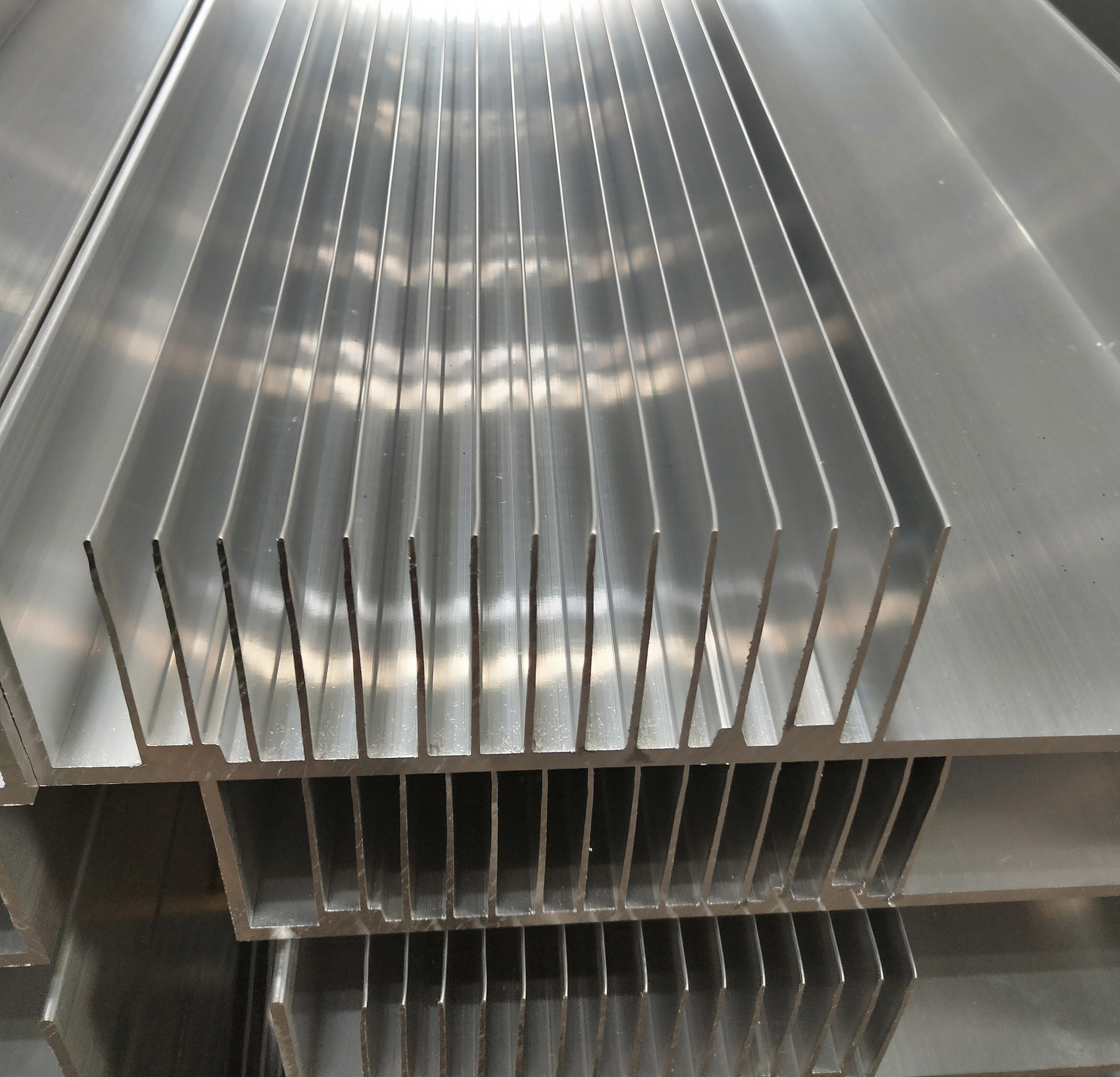

6061 T5 Heat Sink Aluminum Extrusion / OEM Aluminum Radiator Heat Sink / Aluminium For Led Heat Sink

Heat Sink Aluminum Extrusion | Machined Aluminum Parts Suppliers

Certificate Aluminum Profile System Competitive Advantage

-

Engineering design and support.

-

Aluminium profiles deeply processing:cutting,punching,drilling,milling,and fabricating.

-

High Quality system, strictly inspection during production and whole inspection before package.

-

Good performance, product warranty for 15 years.

extruded aluminum t slot

2. Strict quality control and inspection before goods delivery.

3. Production standards: GB5237-2008, QUOLANOD, JIS or other International standards.

4. With 23 years experience, our factory is well recognised by clients and enjoys a good reputation among overseas markets.

5.While being awarded various honors, our brand Yalian Aluminium Profiles is rated as Guangdong Famous Brand by the government and our factory is rated as the enterprise which can always honor our contracts and keep commercial integrity.

6. Strong R&D team and over 100 national patents.

| Aluminium Alloy Chemical Composition | ||||

| Alloy | 6063 (%) | 6063A (%) | 6061 (%) | 6082 (%) |

| Si | 0.2~0.60 | 0.3~0.60 | 0.4~0.80 | 0.7~1.30 |

| Fe | 0.35 | 0.15~0.35 | 0.70 | 0.50 |

| Cu | 0.10 | 0.10 | 0.15~0.40 | 0.10 |

| Mn | 0.10 | 0.15 | 0.15 | 0.40~1.0 |

| Mg | 0.45~0.90 | 0.60~0.90 | 0.80~1.20 | 0.6~1.20 |

| Cr | 0.10 | 0.05 | 0.04~0.35 | 0.25 |

| Zn | 0.10 | 0.15 | 0.25 | 0.20 |

| Ti | 0.10 | 0.10 | 0.15 | 0.10 |

| Other (each) | 0.05 | 0.05 | 0.05 | 0.50 |

| Other (total) | 0.15 | 0.15 | 0.15 | 0.15 |

| Al | Remainder | Remainder | Remainder | Remainder |

| Item | ALUMINUM PROFILE | ||||||

| Material | 6000 series Aluminium | ||||||

| Temper | T4 | T5 | T6 | ||||

| Size / Thickness | General profiles thickness from 0.8 to 5.0mm, length from 3m-6m or customized available; Anodize protection film thickness from 8~25 um, powder coating from 40 ~ 120 um. | ||||||

| Shape | Square | Round | Rectangular | Customized | |||

| Application | In furniture, windows&doors, decorations ,industry, construction and so on | ||||||

| Surface treatment | powder coating | electrophoresis | wood grain | anodized | Brushed | Polishing | |

| Colors | Ref powder coating color sheet and customized color available | ||||||

| Deep process | DCNC | Drilling | Milling | Cutting | Welding | bending | assembling |

| Certificate | CQM, SGS, CE, BV, SONCAP / GB, ISO, JIS, AS, NZS, QUALICOAT, QUOLANOD available | ||||||

| Material & Temper | Aluminum Alloy 6063-T5,6061-T6 |

| Film Standard | Anodized:7-23 μ , Powder coating: 60-120 μ , Electrophoresis film: 12-25 μ. |

| Length | 5.8M or Customized. |

| Thickness | 0.4mm-20mm or Customized. |

| Application | Building and Construction and Decoration. |

| Extrusion Machine | 600-3600 tons all together 6 extrusion lines. |

| Capability | Output 1000 tons per month. |

| Deep Processing | CNC / Cutting / Punching / Checking / Tapping / Drilling / Milling |

| MOQ | 500 kgs. Usually 10-12 tons for a 20'FT; 20-23 tons for a 40HQ. |

| OEM | Available. |

Recommend Products

-

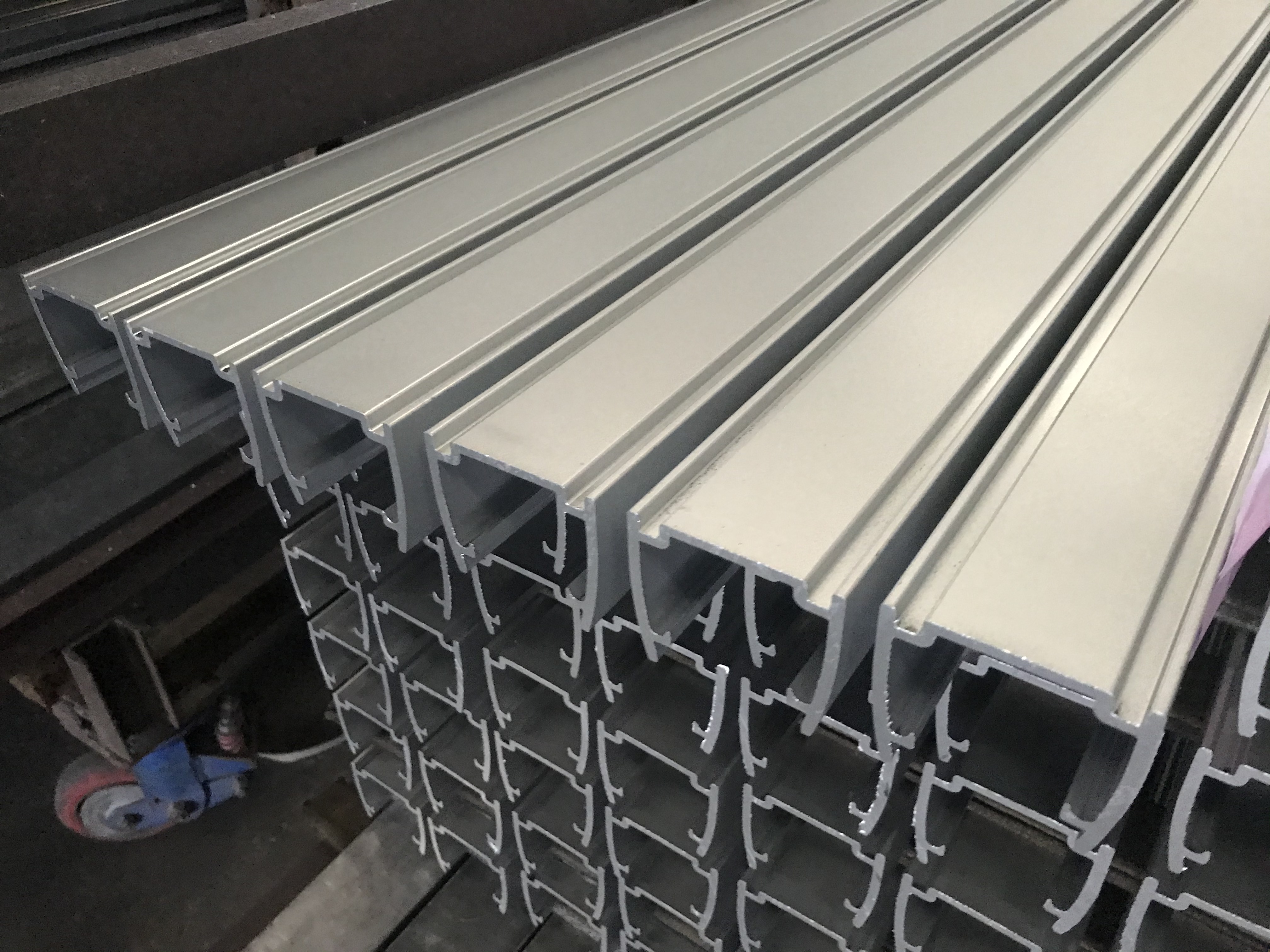

Aluminium Extruded Sections | Net processing Aluminium Alloy Use for Industrial Extrusion Profile Aluminium

Service We provide: 1. Professional technical team Suggestions improvement for you about your product drawings. 2. Professional quality inspectors to Ensure the quality and compliance of your products. 3. Professional

-

Aluminium Alloy Use for Industrial Extrusion Profile Aluminium /Windows profile | Aluminum Profile for Door and Window

Zeao industrial aluminum profile adopts corrosion-resistant 6063-T5, 6061-T6 Aluminum Alloy with a clear anodize finish. Not only do our Slotted Aluminum Profiles come in a variety of standard lengths and sizes, we

-

T5 Aluminium Alloy Use for Industrial Extrusion Profile Aluminium | extruded aluminium profiles

Product Description Ze'ao t slot profile v-slot adopts corrosion-resistant 6063-T5, 6061-T6 Aluminum Alloy with a clear anodize finish. Not only do our Slotted Aluminum Profiles come in a variety of standa

-

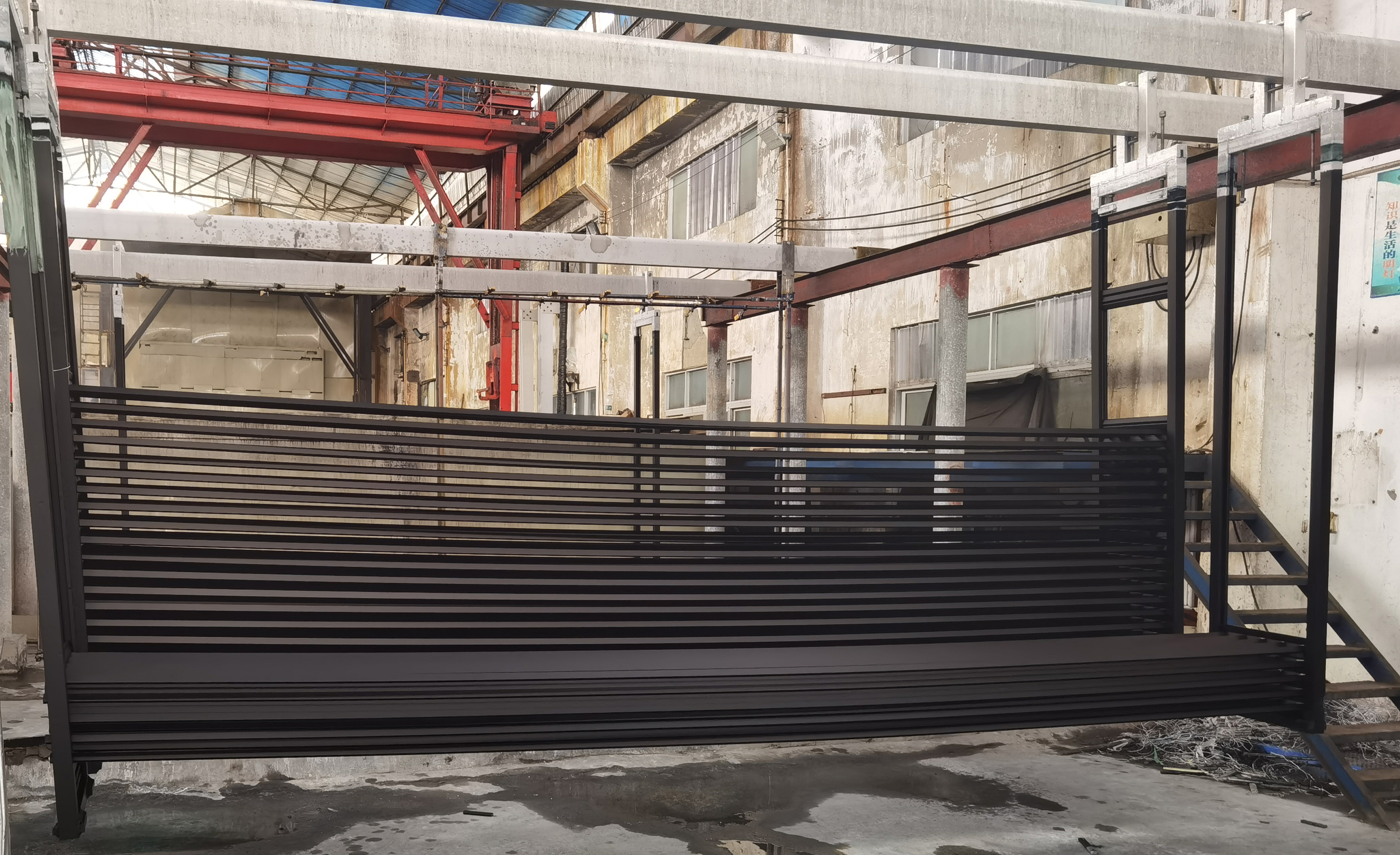

Commercial System Sliding Window | Aluminium Window |Sliding Door |Awning Window | Casement Window of Aluminum Sliding Window and Door with Mosquito Net | sliding aluminum door

Ze'ao as Door and Window Aluminum Profile manufacturer, has more than 10 years of experience. The factory covers an area of 23,000 m2. We are available to provide aluminum profile for door and win

-

Anodized Aluminum Heat sink Extrusion Profile / Aluminum Heat Sink | heat sink aluminum extrusion

Service We provide: 1. Professional technical team Suggestions improvement for you about your product drawings. 2. Professional quality inspectors to Ensure the quality and compliance of your products. 3. Professional