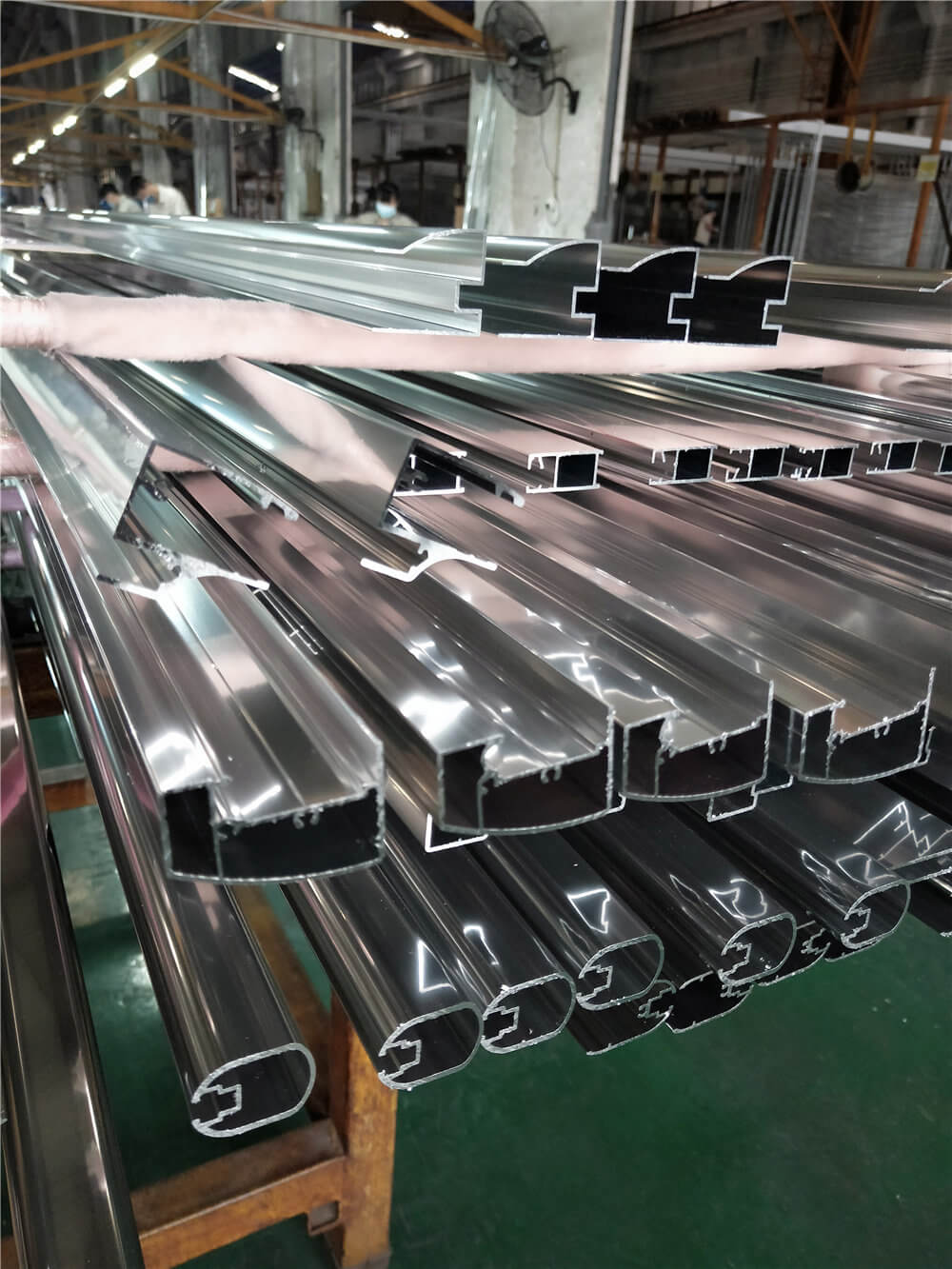

anodized aluminum sheet VS anodized stainless steel

Anodized aluminum plate

Process flow:

Anodized aluminum plate is an aluminum plate that is placed in the corresponding electrolyte (such as sulfuric acid, chromic acid, oxalic acid, etc.) as an anode. Under specific conditions and applied current, a thin layer of aluminum oxide is formed on the oxidation surface of the aluminum plate of the electrolytic anode. The thickness is The hard anodized film of 5-20 microns can reach 60-200 microns.

Material performance:

The most attractive thing about anodized aluminum panels is that it has strong decorative and weather resistance. Compared with other curtain wall materials, it is lighter, and has strong stain resistance, low maintenance costs. Anodized stainless steel, after drawing treatment, but its resistance Corrosion and rust resistance will be relatively reduced, so anodizing treatment after wire drawing can prevent corrosion and wear resistance. To achieve the dual role of protective decoration, the service life will also be lengthened.

Anodized stainless steel

Material technology:

Polishing / sandblasting / wire drawing → degreasing → masking → anodizing 1 → anodizing 2 → sealing → drying

Material performance:

The performance advantages of anodized aluminum plate, it basically has such as corrosion resistance, durability, easy processing and welding, excellent high temperature resistance and low temperature toughness, etc.

If you are interested in anodized aluminum sheet,You can browse related products and initiate consultations on our website.

Process flow:

Anodized aluminum plate is an aluminum plate that is placed in the corresponding electrolyte (such as sulfuric acid, chromic acid, oxalic acid, etc.) as an anode. Under specific conditions and applied current, a thin layer of aluminum oxide is formed on the oxidation surface of the aluminum plate of the electrolytic anode. The thickness is The hard anodized film of 5-20 microns can reach 60-200 microns.

Material performance:

The most attractive thing about anodized aluminum panels is that it has strong decorative and weather resistance. Compared with other curtain wall materials, it is lighter, and has strong stain resistance, low maintenance costs. Anodized stainless steel, after drawing treatment, but its resistance Corrosion and rust resistance will be relatively reduced, so anodizing treatment after wire drawing can prevent corrosion and wear resistance. To achieve the dual role of protective decoration, the service life will also be lengthened.

Anodized stainless steel

Material technology:

Polishing / sandblasting / wire drawing → degreasing → masking → anodizing 1 → anodizing 2 → sealing → drying

Material performance:

The performance advantages of anodized aluminum plate, it basically has such as corrosion resistance, durability, easy processing and welding, excellent high temperature resistance and low temperature toughness, etc.

If you are interested in anodized aluminum sheet,You can browse related products and initiate consultations on our website.