Characteristics of Different Series of Aluminum Coils

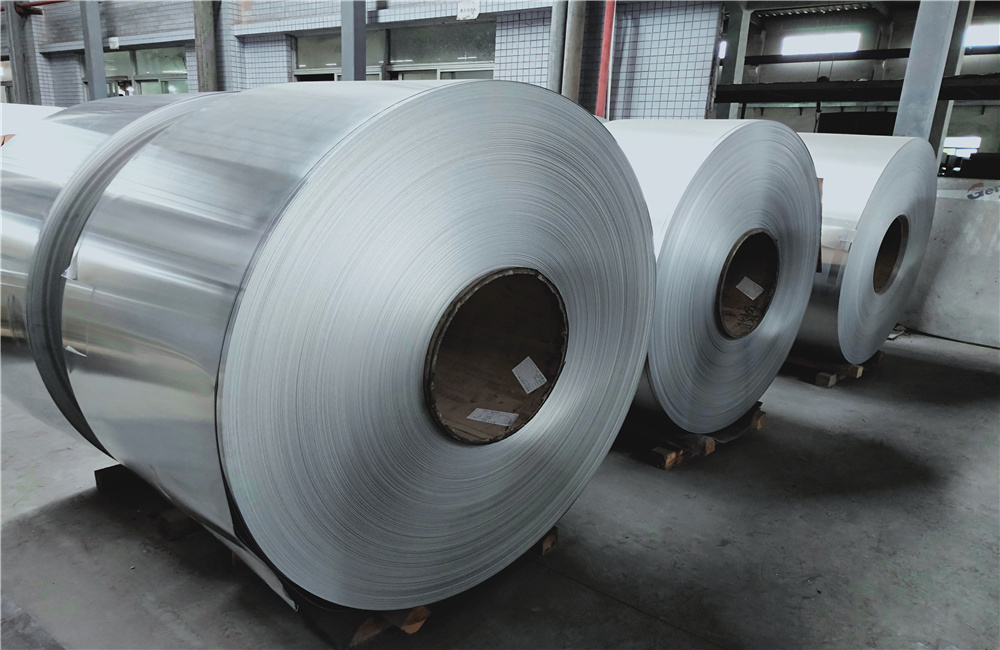

Aluminum coil is a metal product obtained by flying shear after rolling and bending. Aluminum coils are widely used in electronics, packaging, construction, machinery, and other fields.

According to the different metal elements contained in aluminum coils, aluminum coils can be roughly divided into 9 categories, which can be divided into 9 series. Here are introductions of few series to give you a better understanding of aluminum coil products.

1 Series

Features:

The aluminum content of the 1 Series aluminum coil is more than 99.0%, which is easy to process and is one of industrial pure aluminum. This series of aluminum coils have high plasticity, excellent electrical conductivity, thermal conductivity, reflectivity, and corrosion resistance. The strength can be improved by cold working,

Applications:

1 Series aluminum coil has the simplest production process and the widest application range, mainly including automotive aluminum alloy, 3C products, computer brackets, high-end curtain wall panels, cans, shutters, aluminum furniture, door handles, and so on.

3 Series

Features:

The main component of the 3 Series aluminum coil is manganese, which has good formability, weldability, and corrosion resistance. It adopts a cold working method to improve its mechanical properties, and its plasticity is low when it is hardened by cold working.

Applications:

It is commonly used in the manufacture of power battery shells for light vehicles, storage tanks on transportation equipment, food storage devices, cooking utensils, sheet metal pressure vessels, and pipes, etc.

5 Series

Features:

The main alloying element of the 5 Series alloy aluminum coil is magnesium, which does not need heat treatment to strengthen, and has good plasticity when semi-cold hardened, good corrosion resistance, and good weldability. The alloy is characterized by high strength, excellent fatigue resistance, high plasticity, and corrosion resistance.

Applications:

5 Series aluminum coils are widely used in the manufacture of hardware products, electrical enclosures, lubricating oil pipes, ship sheet metal parts, instruments, street lamp brackets, molds, etc.

8 Series

Features:

The main component of the 8 Series aluminum coil is lithium, and Al-Li alloy has good ductility, which effectively reduces the processing difficulty of the Al-Li alloy and prolongs its service life. 8 Series aluminum coil has the characteristics of lightweight, high strength, strong deformation resistance, and strong environmental adaptability.

Applications:

8 Series aluminum coil is seldom used in the industrial fields, generally used in the production of aluminum foil, and widely used in food and drug industries.

8 Series aluminum coil is an aluminum plate mainly used as a bottle cap and also used in radiators.

Conclusion

Different series of aluminum coils can play a better role in the corresponding fields.

ZEAO is a modern aluminum processing enterprise integrating scientific research, processing and manufacturing. We can produce 1-8 series aluminum foil products with complete specifications, which can meet your personalized processing needs. We look forward to discussing more knowledge about Aluminum with you.