What is the Aluminum extrusion profile?

What is meant by Aluminum extrusion?

The process of aluminum extrusion can be understood as a pressure head pushing the aluminum alloy material through a specific mold to make it come out of the mold opening.An aluminium billet is a form of primary aluminium. The softened aluminium billet is transferred to the press vessel and forced through the vessel by applying a certain pressure to obtain a uniformly shaped aluminium, the aluminium extrusion.

The difference between aluminum and extruded aluminum

Aluminum can be divided into extruded aluminum and cast aluminum. Both have their advantages and disadvantages, but both methods are cheaper than machining parts from solid bodies.

Aluminum castings

And the casting is the process of pouring molten aluminum into a mold to solidify it.

Aluminum castings are often used to produce large parts. The initial mold cost of cast aluminum is relatively high, limited to low melting point metals (aluminum, magnesium, copper), and the mold life may be short. Although the casting aluminum may produce smaller tolerances, the casting may contain some porosity, and the surface finish of the casting may require machining.

Aluminum extrusion

Aluminum extrusion process

Aluminum extrusion is a process whereby heated alloy material is pushed through a die to create a part with a specific cross-sectional profile.

Due to lower start-up costs and stronger aluminum extrusion products, the aluminum extrusion process is a better choice for shorter production cycles.

The extrusion process makes use of many of the beneficial physical properties of aluminium itself. The use of aluminium has become a versatile and consistent method of producing simple to complex aluminium profiles.

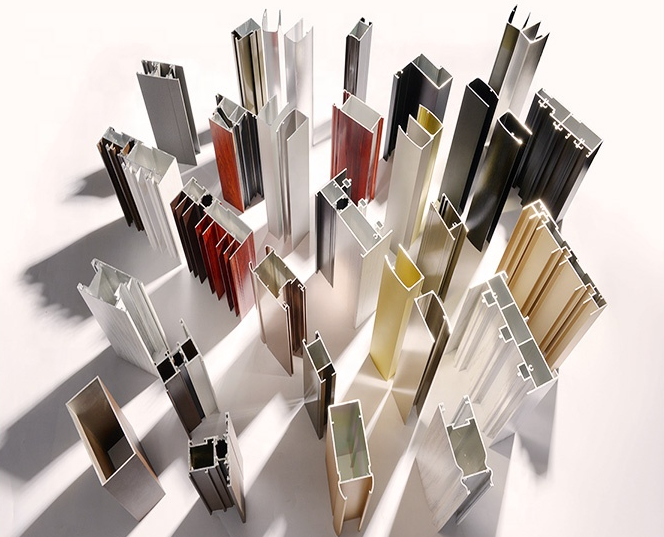

What Shapes Can be Extruded?

There are three main types of finished aluminum extrusions: solid (without voids or openings, i.e. rods or beams), semi-hollow (with partially closed voids, i.e. with narrow gap channels), and

hollow (with one or more voids, i.e. square or rectangular tubes).

The shape of the aluminum extrusion product can be simple or complex. Different aluminum extruders produce different sizes of aluminum profiles, the larger the size of the aluminum, the larger the extruder used. It can produce door and window profiles, curtain wall material, industrial building materials, and so on.

Why is aluminum extrusion so popular?

Aluminum material is a product made of aluminum and other alloying elements.

Aluminum extrusion materials are usually made by hot-melt extrusion of aluminum rods to obtain different aluminum profile sections, and various surface treatments to obtain aluminum profiles with different appearances.

Industrial aluminum profiles are becoming more and more common and have become an indispensable industrial raw material in modern society.

Compared with iron and stainless steel, aluminum profile show the following advantages:

● The low-cost extrusion process, simple process, and easy installation and dismantling.

● Wide range of aluminum material products and production flexibility.

● Non-toxic, environmentally friendly, and recyclable.

● A variety of surface treatment effects (e.g. electrophoretic coating, powder-coated abrasive cloth, etc.)

● Strong corrosion resistance, extruded shape aluminum profiles are more robust and durable.

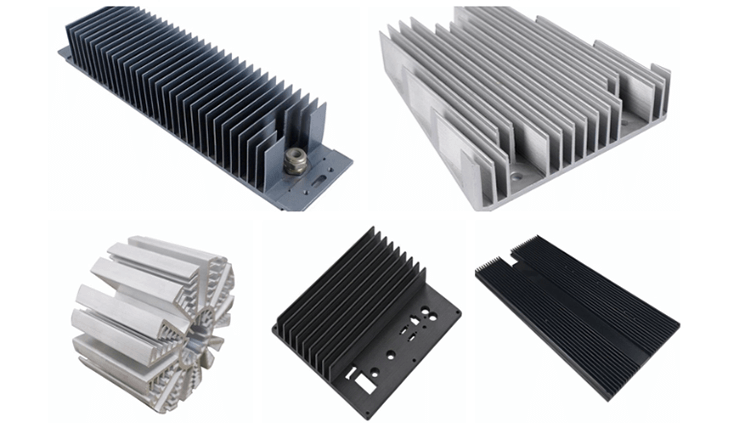

4 Types of extrusion aluminum profiles

According to different application industries, four types of extruded aluminum profiles are listed below:

General Profile

T5 aluminum round tube square is a high-quality anodized aluminum extrusion. It can be used for furniture components, automotive parts, etc.

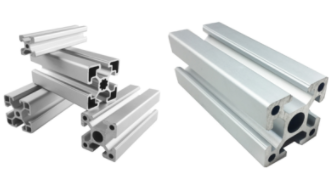

Industrial Profiles

It is made of corrosion-resistant 6063-T5 and 6061-T6 aluminum alloy, which has been anodized. Slotted aluminum profiles have a variety of standard lengths and sizes to meet the specific needs of different projects.

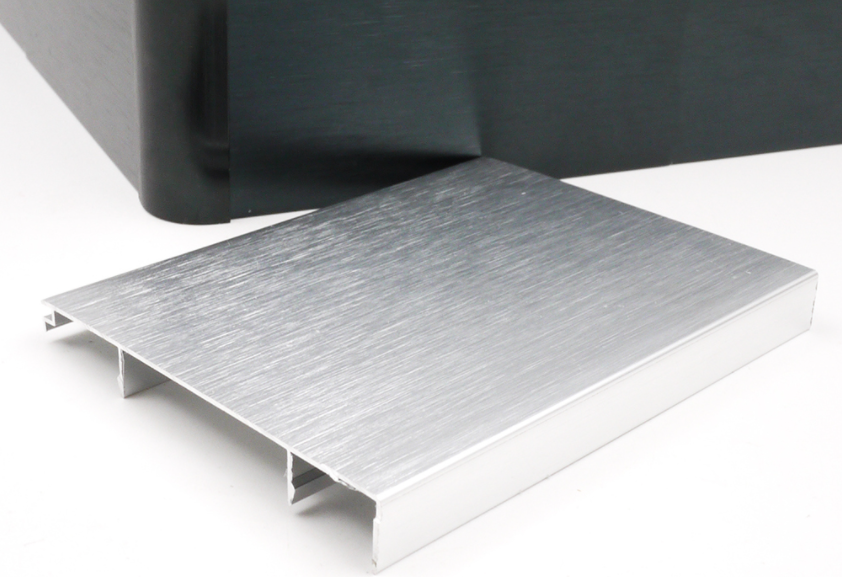

Decorative Profiles

Decorative aluminum profiles have high processing accuracy, improve product tolerance requirements and reasonable assembly, and are often used for composite floor wall aluminum baseboards and aluminum baseboard covers.

Building Material

Aluminum building materials use healthy and environmentally friendly materials, which are rich in variety, corrosion-resistant, and waterproof.

Although aluminum cannot form the basic framework of a building, it assists in the internal structure. Lighting equipment, elevator shafts, and stairwells are all used in different applications. Aluminum extrusion design is indispensable in almost all construction fields.

Outdoor Building Materials Aluminum Profile

Applications of Extruded Aluminium

Aluminum profiles are both strong and lightweight and can be easily manipulated manually. Aluminum extrusions are even specified as part of weight reduction work. Aluminum extrusions are most commonly found in industrial automation and are increasingly being used as frames for other consumer products, such as in the electronics, automotive, household, construction industries, and so on.

Electronic

Workbenches and consoles for the electronics industry are assembled from aluminium profiles and aluminium panels or other materials that are not only corrosion resistant but also very easy to clean.

Transportation

The demand for aluminum extrusions used as parts for light-duty automobile manufacturing is also increasing, such as the body, roof rails, and chassis of common vehicles.

Home Equipment

The most common are aluminum doors and windows, bookcases, computer desks, shoe racks, and currently very popular aluminum wardrobes and kitchen cabinets. Weighing the pros and cons in terms of service life, cost performance, etc., aluminium doors and windows have gradually replaced doors and windows of other materials.

Building Material

Extruded aluminum parts maintain strength, flexibility, and corrosion resistance under load, and can resist deformation caused by weather. Different alloys are added to the aluminum profile, which is very strong and has a certain load-bearing capacity. On the basis of lightweight, it ensures safe performance and prolongs its service life.

Conclusion

ZEAO is one of the customized and OEM aluminum extrusion companies. Professionals will help you design aluminum profiles that meet your needs. Please contact us if you want to know more about the extrusion process and parts.