Color CNC Machining Parts | cnc aluminum parts | CNC Machining Aluminum Suppliers

Our machine shop offers an unrivaled expertise in precision aluminum part machining and finishing; no one knows the demands and challenges of cnc aluminum part better than zeao Metal Tech.

Colored Aluminum Coil | CNC Machining Aluminum Suppliers - ZEAO

CNC Machining Aluminum Parts

6061-T6 aluminum properties include its structural strength and toughness. It is also offers good finishing characteristics and responds well to anodizing, including clear, clear and color dye, and hardcoat. 6061 aluminum alloy is also easily welded and joined. However, in its –T6 condition the welds may lose some strength, which can be restored by re-heat-treating and artificially aging.

Aluminum in its purest form is too soft and reactive to be of structural use. However, its alloys, such as 6061-T6 alloy, make it structurally stronger and more useful in the manufacturing of durable products.

6061-T6 aluminum properties make it a material of choice for builders of boats and watercraft because it’s strong and lightweight. It is ideal for sailboat masts and for hulls of larger yachts that cannot be made from fiberglass. Small, flat-bottom canoes are almost entirely fabricated from 6061-T6, although the bare aluminum is often coated with protective epoxy to improve its resistance to corrosion.

Other common applications of 6061-T6 aluminum include bicycle frames, applications where heat transfer is required, such as heat exchangers, air coolers and heat-sinks, and applications where 6061-T6’s non-corrosive characteristics are important, such as water, air and hydraulic piping and tubing.

Aluminum 6061-T6 alloy conducts and dissipates heat well. Since it can be extruded, it can be formed into almost any imaginable shape.

Application:

cnc aluminum parts

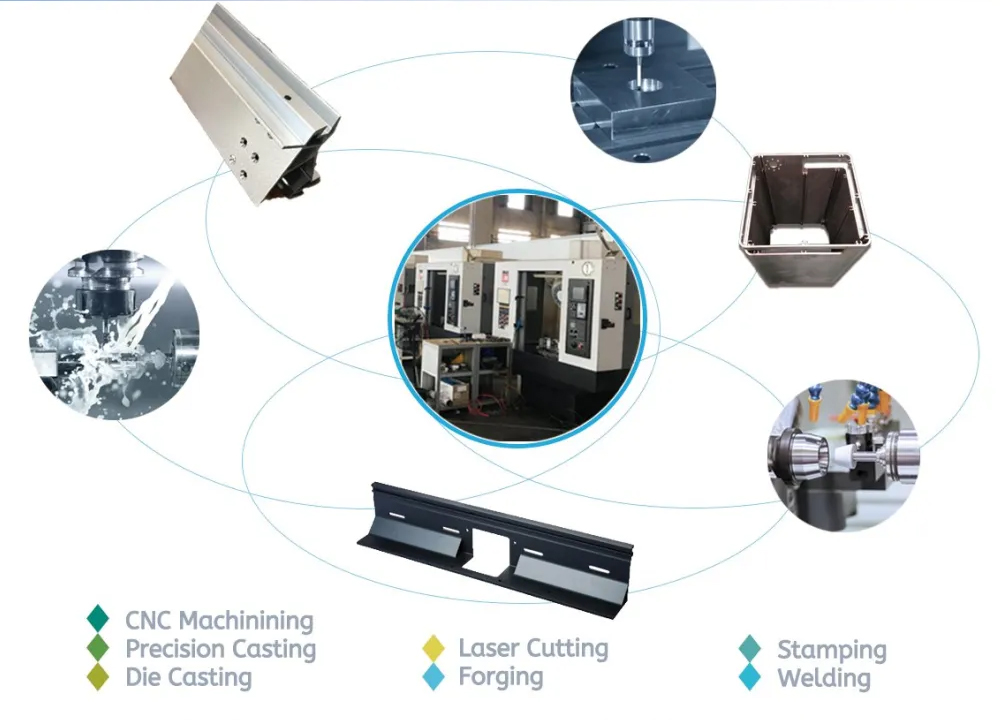

- cnc machining 2.precision 3.die casting 4.laser cutting 5.forging 6.stamping 7.welding

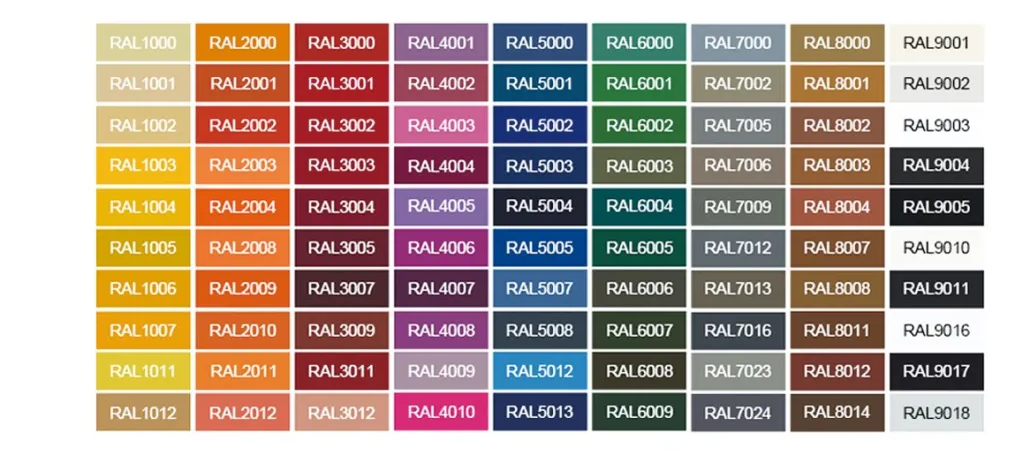

Color sample

In today's highly competitive market, having a product that stands out is essential. One way to achieve this is by using custom parts that meet your specific requirements. CNC machining is a popular method for creating such parts due to its high accuracy and repeatability. And when color is added to CNC machined parts, it can enhance the functionality, visibility, and overall aesthetic appeal of the final product. In this article, we will explore colored CNC machining parts and how they can benefit your product.

About Zeao

At Zeao, we are experts in CNC machining, and we can make custom parts in a wide range of colors and materials. Our skilled technicians and state-of-the-art machines make sure that each part is made to the highest standards of quality and accuracy. Because we know a lot about color CNC machining, we can help you make custom parts that meet your needs and make your product better.

The Benefits of Color CNC Machining Parts

Adding color to CNC machined parts can provide many benefits, including:

-

Enhanced functionality: Choosing the right color can help improve the functionality of the part. For example, a highly visible color can make the part easier to identify and sort during assembly.

-

Improved visibility: Using a bright color can improve the part's visibility, especially in low-light conditions. This can be important for parts used in safety-critical applications.

-

Aesthetic appeal: The part's color can have a big effect on how it looks as a whole. Choosing the right color can enhance the aesthetic appeal of the final product.

-

Branding: Using a specific color scheme or the company's colors can help strengthen brand identity and make the product more recognizable.

Coloring Methods for CNC Machined Parts

There are several methods for adding color to CNC machined parts, including:

-

Colored raw materials: Many materials, such as plastics and metals, are available in a range of colors. Using colored raw materials can be a cost-effective and efficient way to add color to parts.

-

Painting and powder coating: Painting or powder coating the parts can give them a wide range of colors and finishes, including metallic and matte finishes.

-

Anodizing: Anodizing is a surface treatment process that can be used to add color to metals like aluminum. It provides excellent corrosion resistance and can also enhance the appearance of the part.

Factors to Consider When Selecting a Color

When selecting a color for your CNC machined parts, it's important to consider several factors, including:

-

Functionality: The color of the part should enhance its functionality. For example, a highly visible color may be important for parts used in safety-critical applications.

-

Branding: The color of a part can be used to strengthen the brand and make it easier to recognize the product.

-

Aesthetic appeal: The part's color can have a big effect on how it looks as a whole. Choosing the right color can enhance the aesthetic appeal of the final product.

-

Cost: The cost of coloring the parts should also be considered. Some coloring methods, like using colored raw materials, may be more cost-effective than others, like painting or anodizing.

Commonly Used Colors in CNC Machining

Here are some commonly used colors in CNC machining and their properties:

-

Black: Black is a versatile, neutral color that makes things easy to see and is resistant to corrosion. It's a popular choice for many applications.

-

Red: Red is a very noticeable color that can be used to show danger or to show that something is very important. It provides good corrosion resistance and can be easily anodized.

-

Blue: Blue is a calm, professional color that can show accuracy or dependability. It's a popular choice for many applications.

-

Green: Green is resistant to corrosion and can be used to show safety or care for the environment. It's a popular choice for parts used in outdoor environments.

- Yellow: Yellow is a very noticeable color that can be used to warn of or show how important something is. It provides good visibility in low-light conditions.

Colored CNC-machined parts can help in a lot of ways, such as making them work better, be easier to see, and look better. When selecting a color for your CNC machined parts, it's important to consider the intended use of the part, the desired appearance, and the cost of coloring. At Zeao, we specialize in CNC machining and can provide custom parts in a wide range of materials and colors. Our experienced technicians and state-of-the-art machines ensure that every part is made to the highest standards of quality and precision. Contact us today to learn more about our color CNC machining services and how we can enhance your product.

| Business Type | Manufacturer |

| Advantage |

1. Zeao is factory providing CNC machining service for more than 10years, we focus on client's demand and client's satisfaction. 2. Provide 2D & 3D drawing for modifying 3. Competitive price with good quality 4. Small order is acceptable 5. Short delivery time (7-25days according to order Qty) 6. Customized size and specification /OEM available 7. Near Shenzhen and Guangzhou, convenient transportation |

| Application |

Automobile, Motorcycle, Bicycle, Scooter, Machinery, electronics, furniture, construction and other industrial uses. |

Materials Available of CNC Machining

| Materials Available | Aluminum | Al6061, Al6063,AL7075,AL5052 etc |

Better services of CNC machining:

| (Payment Terms/Trade Term/Shipment Terms/ ): | |

| Our Processing | CNC machining, CNC milling and turning, drilling, grinding, bending, stamping, tapping, injection |

| Surface finish | Zinc-plated, nickel-plated, chrome-plated, silver-plated, gold-plated, imitation gold-plated, |

| Tolerance | 0.05mm~0.1mm |

| QC System | 100% inspection before shipment |

| Drawing format | CAD / PDF/ DWG/ IGS/ STEP |

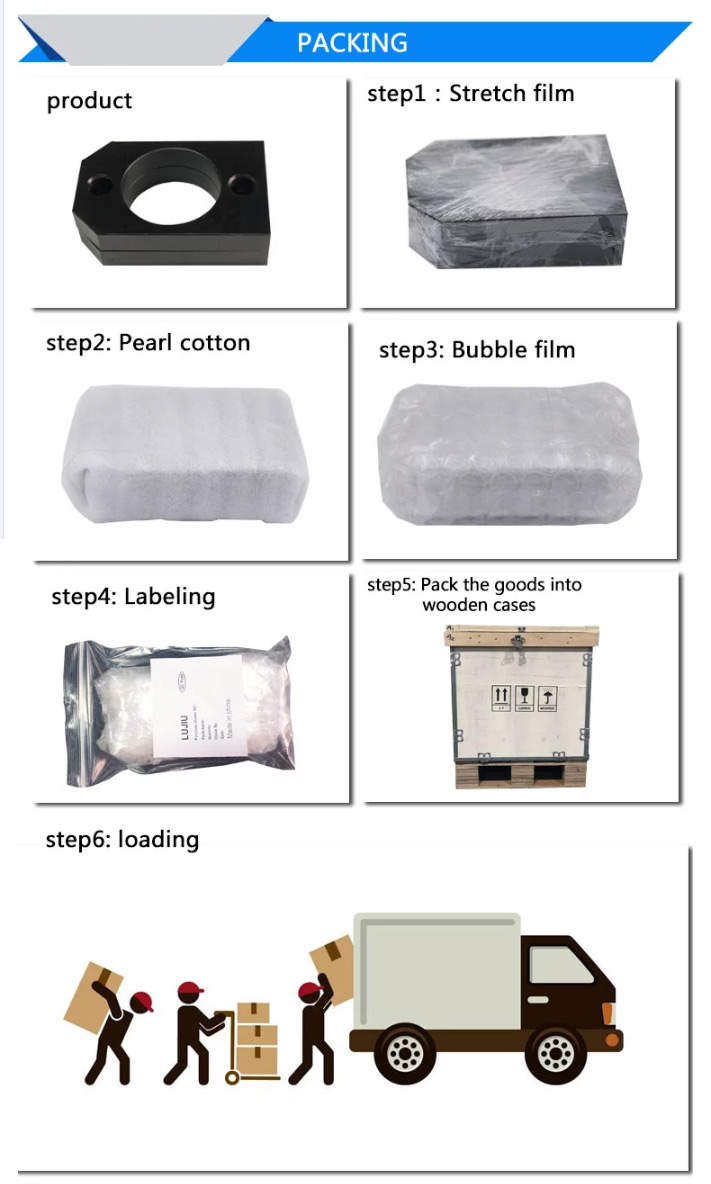

| Packaging | Standard package / Carton or Pallet / As per customized specifications |

| Payment Terms | 30 -50%T/T in advance, 70-50% balance before delivery; Pay Pal or Western Union is acceptable. |

| Trade terms | EXW, FOB, CIF, As per customer's request |

| Shipment Terms |

1) 0-100kg: express & air freight priority 2) >100kg: sea freight priority 3) As per customized specifications |

| Note |

All cnc machining parts are custom made according to customer's drawings or samples, no stock. If you have any cnc machining parts to be made, please feel free to send your kind drawings/samples to us |

Application

Automobile, Motorcycle, Bicycle, Scooter, Machinery, electronics, furniture, construction and other industrial uses.

Recommend Products

-

Color CNC Machining Parts | cnc aluminum parts | CNC Machining Aluminum Suppliers

Zeao is a manufacturer of cnc machining parts with factory who has a strong products develop team with many experienced workers; We manufacture custom CNC machined parts according to your drawings or existing sample

-

cnc aluminum parts | Zeao high quality CNC Machining Parts

Zeao Industrial is a leading manufacturer of CNC machined Parts in China. We provide CNC Machined Parts , CNC milling & turning parts , CNC Precision Turned Part and Aluminum CNC Machined Parts o

-

Factory High Precision Automatic Production Custom Aluminum Extrusion CNC Machining Parts CNC Aluminum Parts

Ze'ao Industrial is a leading manufacturer of CNC machined Parts in China. We provide CNC Machined Parts , CNC milling & turning parts , CNC Precision Turned Part and Aluminum CNC Machined Pa

-

OEM Precision CNC Machined Aluminum Parts Germany Auto

Zeao is a manufacturer of cnc machining parts with factory who has a strong products develop team with many experienced workers; We don't offer any ready made cnc machining parts and are manufacturing the

-

cnc aluminum parts | Alulminum Machinery Part/High Precision CNC Machining Part | aluminium hollow section

Zeao is a manufacturer of cnc machining parts with factory who has a strong products develop team with many experienced workers; We don't offer any ready made cnc machining parts and are manufacturing the custom