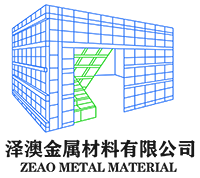

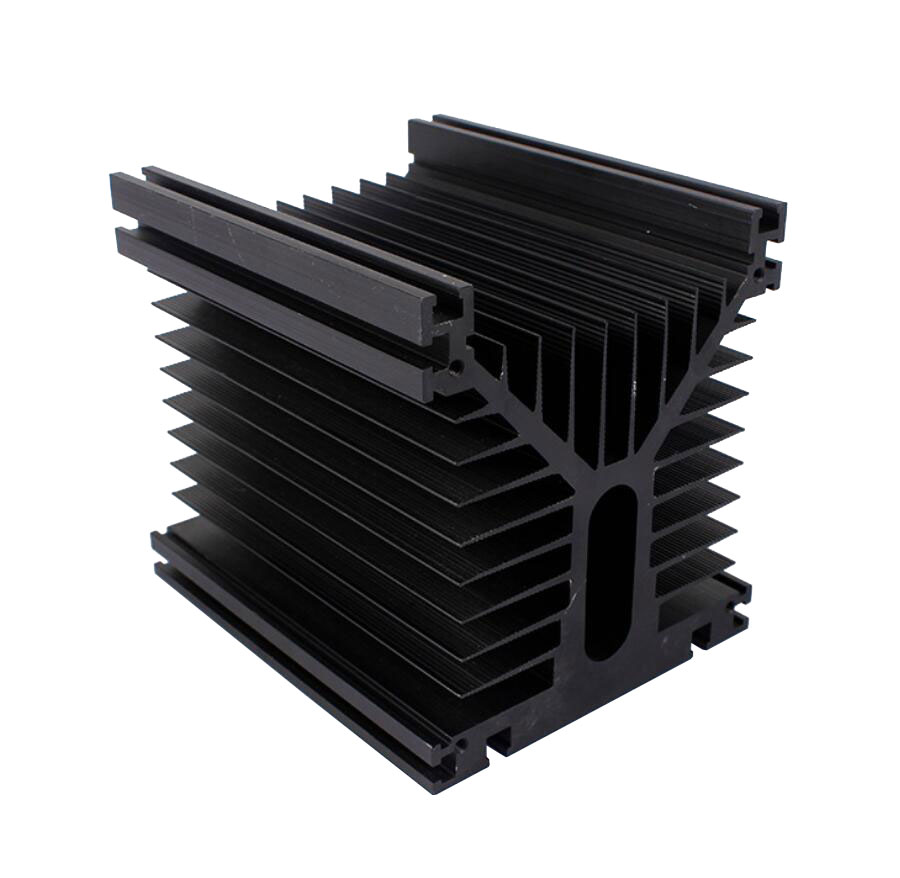

Anodized Aluminum Heat sink Extrusion Profile / Aluminum Heat Sink | heat sink aluminum extrusion

1. Professional technical team Suggestions improvement for you about your product drawings.

2. Professional quality inspectors to Ensure the quality and compliance of your products.

3. Professional staff to match custom colors for you,make samples for you if you need.

4. Professional die development capabilities.

5. Professional aluminum manufacturer experience

Heat Sink Aluminum Extrusion | CNC Aluminium Parts Manufacturers

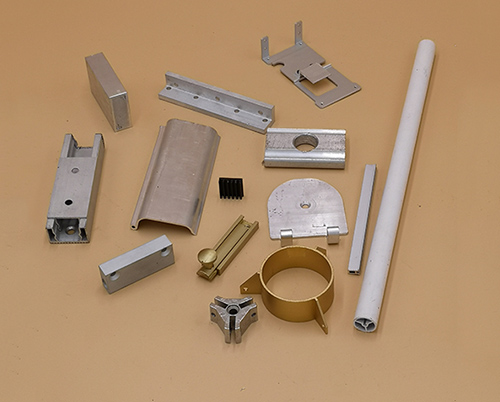

CNC Machining Aluminum Parts

6061-T6 aluminum properties include its structural strength and toughness. It is also offers good finishing characteristics and responds well to anodizing, including clear, clear and color dye, and hardcoat. 6061 aluminum alloy is also easily welded and joined. However, in its –T6 condition the welds may lose some strength, which can be restored by re-heat-treating and artificially aging.

Aluminum in its purest form is too soft and reactive to be of structural use. However, its alloys, such as 6061-T6 alloy, make it structurally stronger and more useful in the manufacturing of durable products.

6061-T6 aluminum properties make it a material of choice for builders of boats and watercraft because it’s strong and lightweight. It is ideal for sailboat masts and for hulls of larger yachts that cannot be made from fiberglass. Small, flat-bottom canoes are almost entirely fabricated from 6061-T6, although the bare aluminum is often coated with protective epoxy to improve its resistance to corrosion.

Other common applications of 6061-T6 aluminum include bicycle frames, applications where heat transfer is required, such as heat exchangers, air coolers and heat-sinks, and applications where 6061-T6’s non-corrosive characteristics are important, such as water, air and hydraulic piping and tubing.

Aluminum 6061-T6 alloy conducts and dissipates heat well. Since it can be extruded, it can be formed into almost any imaginable shape.

Application - anodized aluminum strip:

cnc aluminum parts

Color sample

heat sink aluminum extrusion

| Aluminium Alloy Chemical Composition | ||||

| Alloy | 6063 (%) | 6063A (%) | 6061 (%) | 6082 (%) |

| Si | 0.2~0.60 | 0.3~0.60 | 0.4~0.80 | 0.7~1.30 |

| Fe | 0.35 | 0.15~0.35 | 0.70 | 0.50 |

| Cu | 0.10 | 0.10 | 0.15~0.40 | 0.10 |

| Mn | 0.10 | 0.15 | 0.15 | 0.40~1.0 |

| Mg | 0.45~0.90 | 0.60~0.90 | 0.80~1.20 | 0.6~1.20 |

| Cr | 0.10 | 0.05 | 0.04~0.35 | 0.25 |

| Zn | 0.10 | 0.15 | 0.25 | 0.20 |

| Ti | 0.10 | 0.10 | 0.15 | 0.10 |

| Other (each) | 0.05 | 0.05 | 0.05 | 0.50 |

| Other (total) | 0.15 | 0.15 | 0.15 | 0.15 |

| Al | Remainder | Remainder | Remainder | Remainder |

| Item | ALUMINUM PROFILE | ||||||

| Material | 6000 series Aluminium | ||||||

| Temper | T4 | T5 | T6 | ||||

| Size / Thickness | General profiles thickness from 0.8 to 5.0mm, length from 3m-6m or customized available; Anodize protection film thickness from 8~25 um, powder coating from 40 ~ 120 um. | ||||||

| Shape | Square | Round | Rectangular | Customized | |||

| Application | In furniture, windows&doors, decorations ,industry, construction and so on | ||||||

| Surface treatment | powder coating | electrophoresis | wood grain | anodized | Brushed | Polishing | |

| Colors | Ref powder coating color sheet and customized color available | ||||||

| Deep process | DCNC | Drilling | Milling | Cutting | Welding | bending | assembling |

| Certificate | CQM, SGS, CE, BV, SONCAP / GB, ISO, JIS, AS, NZS, QUALICOAT, QUOLANOD available | ||||||

| Material & Temper | Aluminum Alloy 6063-T5,6061-T6 |

| Film Standard | Anodized:7-23 μ , Powder coating: 60-120 μ , Electrophoresis film: 12-25 μ. |

| Length | 5.8M or Customized. |

| Thickness | 0.4mm-20mm or Customized. |

| Application | Building and Construction and Decoration. |

| Extrusion Machine | 600-3600 tons all together 6 extrusion lines. |

| Capability | Output 1000 tons per month. |

| Deep Processing | CNC / Cutting / Punching / Checking / Tapping / Drilling / Milling |

| MOQ | 500 kgs. Usually 10-12 tons for a 20'FT; 20-23 tons for a 40HQ. |

| OEM | Available. |

Recommend Products

-

Aluminium Extruded Sections | Net processing Aluminium Alloy Use for Industrial Extrusion Profile Aluminium

Service We provide: 1. Professional technical team Suggestions improvement for you about your product drawings. 2. Professional quality inspectors to Ensure the quality and compliance of your products. 3. Professional

-

Aluminium Alloy Use for Industrial Extrusion Profile Aluminium /Windows profile | Aluminum Profile for Door and Window

Zeao industrial aluminum profile adopts corrosion-resistant 6063-T5, 6061-T6 Aluminum Alloy with a clear anodize finish. Not only do our Slotted Aluminum Profiles come in a variety of standard lengths and sizes, we

-

T5 Aluminium Alloy Use for Industrial Extrusion Profile Aluminium | extruded aluminium profiles

Product Description Ze'ao t slot profile v-slot adopts corrosion-resistant 6063-T5, 6061-T6 Aluminum Alloy with a clear anodize finish. Not only do our Slotted Aluminum Profiles come in a variety of standa

-

Commercial System Sliding Window | Aluminium Window |Sliding Door |Awning Window | Casement Window of Aluminum Sliding Window and Door with Mosquito Net | sliding aluminum door

Ze'ao as Door and Window Aluminum Profile manufacturer, has more than 10 years of experience. The factory covers an area of 23,000 m2. We are available to provide aluminum profile for door and win

-

Anodized Aluminum Heat sink Extrusion Profile / Aluminum Heat Sink | heat sink aluminum extrusion

Service We provide: 1. Professional technical team Suggestions improvement for you about your product drawings. 2. Professional quality inspectors to Ensure the quality and compliance of your products. 3. Professional